Advantages of Embossed Vaccum Bag

Sep 13, 2022|

Sep 13, 2022| View:563

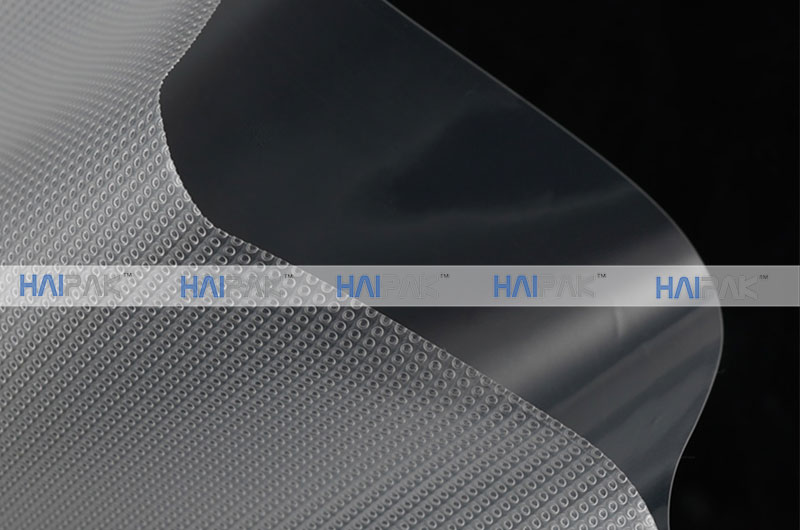

View:563The Embossed Vaccum Bagis designed to remove all the air from the packaging and seal the Bag to maintain a high degree of decompression. The lack of air is equivalent to the effect of low oxygen, making it impossible for microorganisms to survive, in order to achieve the fruit fresh, disease-free rot occurred. The main advantages of the Embossed Vaccum Bag are as follows:

High Barrier: the use of different plastic materials with high barrier properties co-extruded film, to oxygen, water, carbon dioxide, smell, and other high barrier effects.

Performance Stability: oil-resistant, moisture-resistant, low-temperature freezing, quality, fresh, and smell, can be used for vacuum packaging, aseptic packaging, and inflatable packaging.

Low cost: compared with glass packaging, aluminum foil packaging, and other plastic packaging, to achieve the same barrier effect, the Embossed Vaccum Bag has a greater cost advantage. Because of the simple process, the production of film products and dry composite films, and other composite films can reduce the cost by 10-20%, flexible specifications: you can meet the different needs of different products.

High Strength: Embossed Vaccum Bag has tensile properties during processing. The strength of the plastic can be increased after drawing, and nylon, polyethylene, and other plastic materials can also be added in the middle, it has more than the general composite strength of plastic packaging, there is no delamination, good flexibility, and good heat sealing performance.

Small volume ratio: Embossed Vaccum Bag can be vacuum shrink packaging, the volume ratio of nearly 100%, this is glass, cans, paper packaging can not be compared.

No pollution: Embossed Vaccum Bag does not add binder, no residual solvent pollution, and green environmental protection.