Product Categories

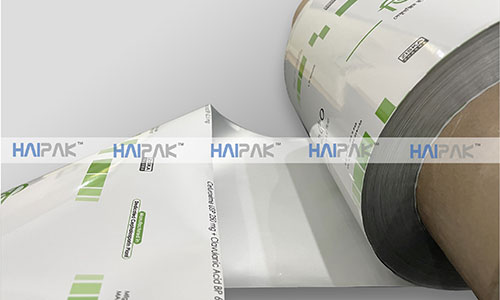

Printed Roll Stock and laminating film on rolls and then using a machine to form a package into which the product is packed and the bag sealed. This method of packaging is unique, flexible, and particularly well suited for packaging a wide range of products. From nuts and snacks to agrochemicals, laminated roll packaging offers the flexibility to protect products from odors, moisture and other environmental stresses.

Haipak is committed to providing customers with the best quality printing roll film as its own responsibility, and strict selection of raw materials.

Through packaging engineering, we can determine the size, shape and material composition suitable for the desired result. As an established manufacturer of packaging equipment, we can determine the compatibility of packaging materials with filling equipment.

We have creative in-house graphic designers to assist with all elements of graphic design, including prototypes and pre-press due diligence.

Fine food / powders / Sports nutrition / Health and beauty / Home care / Horticulture / Liquids / Baby food / Soups/Ssauces/Spices

Haipak printing roll film provides a variety of finishes, such as matt, glossy, metal,plain etc.

Haipak offers customized functionality and barrier properties for your specific web packaging, as well as solvent-free lamination to reduce environmental impact. With a variety of substrates such as PE, PET, BOPP, CPP, nylon, Tyvek, cellophane, PLA, and metallized films, we're sure we'll have one to meet your needs.

High Barrier Web Lamination

We offer high-barrier web laminates with a choice of metallized or transparent films. These film laminates provide maximum durability and longer shelf life for perishable products. High-barrier roll laminates protect product integrity and shield sensitive items from light, moisture, oxygen and other contaminants.

Metallized film laminates

Our metallized film laminates offer superior barrier and adhesion properties. Silver-reflective materials enhance UV protection and improve barrier properties for longer shelf life.

Solvent-free lamination

Solvent-free laminating successfully reduces coating weight, with no risk of emissions and a smaller footprint than solvent laminating. It is primarily used for consumer products, ready-to-eat foods, frozen foods, fresh produce and non-food products that require extended shelf life.

With a wide variety of roll film types and the latest technology and manufacturing processes, Haipak can take your operation to the next level. Our engineering team ensures that every film has excellent moldability, outstanding clarity, uniform thickness and flatness.

OPP/CPP Film Packaging

OPP/CPP film packaging offers high clarity, as well as the ability to print eye-catching graphics to make your merchandise more appealing on the shelf.

Polyethylene (PE) film packaging

Polyethylene (PE) film packaging offers excellent sealing, high moisture resistance and high strength. It can be extruded with EVOH to provide better barrier properties or with high EVA content for improved sealing.

Polyester (PET) film packaging

With polyester (PET) film packaging, you can achieve high clarity and strength while maintaining low thickness and excellent printability. This single-layer, heat-sealed film package is suitable for a variety of applications and can be metallized for additional barrier properties.

Other film substrates

In addition to OPP/CPP, PE and PET film packaging, we offer a variety of other film substrates, such as nylon, Tyvek, PLA and others, which are used in a wide range of applications with excellent gas and moisture barrier properties.

Our roll packaging films for a variety of applications

We produce high-quality roll packaging films that are specially configured for optimal performance and customized to your needs. Our flexible roll packaging is perfect for a variety of applications, from frozen foods to personal care products.

Haipak printing roll film can be used as packaging materials for a variety of products, such as pillow pouches, packets, sachets and lay-flat pouches.

Size:Haipak printing roll film is available in sizes ranging from 100ml to 5L

Printing Process:Haipak printing roll film uses food grade environmentally friendly ink, and up to 10 color gravure print.

Customized Materials:Materials such as OPP / CPP / PET / PE / PP / NY / AL / METPET/KRAFT PAPER is optional,mono or multi-layer , customized service also available.

Customized Features:Easy tearing, hanging hole, window, zipper, etc are optional

Pack Properties: Haipak printing roll film can effectively block air, water and ultraviolet rays to protect your products safety.

Filling And Sealing: Haipak printing roll film is suitable for cold sealing film and hot sealing film of all kinds of dry and wet products. Suitable for filling and sealing of horizontal and vertical types of equipments.

Packaging Advantage: It fits your automatic film wrapping machine perfectly and can be used in horizontal flow wrapper (HFFS), vertical wrapper (VFFS), and in-line pouch machines.

Consistent friction performance

Consistent sealing performance

Consistent barrier protection

Consistent color printing

Reduced downtime

Virtually no film waste

Fast splicing of new film

Faster running speeds