Lidding film manufacturers explain the universal properties of packaging film

Sep 19, 2022|

Sep 19, 2022| View:376

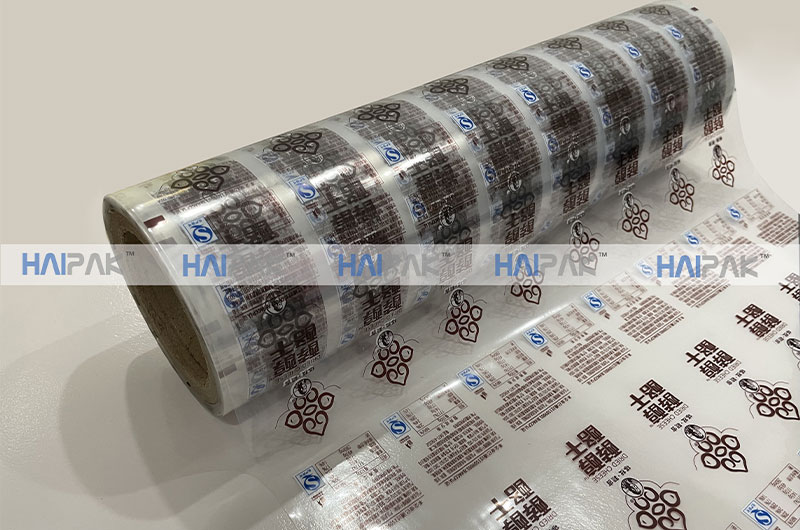

View:376Lidding film manufacturersoften say that the film is made from a mixture of several different grades of polyethylene resin. It has the properties of puncture resistance and high strength. It wraps the goods stacked on the pallets, makes the package more stable and neat, and has a super waterproof effect. Lidding film manufacturers explain that there are four main points about the universal nature of film packaging:

1. Unitization: one of the characteristics of winding film packaging. That is, with the help of super-strong winding force and retraction, the goods are tightly and fixedly bundled into a unit, so that the scattered small pieces become a whole, even in adverse circumstances, the product can ensure that the goods are not loose and separated, so as not to cause damage.

2. Primary Protection: protection of the surface of a commodity. That is, around the commodity to form a very light, protective appearance, so as to achieve dust-proof, oil-proof, moisture-proof, waterproof, and other purposes, so that the packaging goods even force, avoiding damage from the uneven force, lidding film manufacturers say, is something that some traditional packaging methods (binding, packing, tape, etc.) can't do.

3. Compression fixity: with the help of the winding film after stretching the retractable force will be wrapped in goods packaging. That is, to form a compact, space-free unit as a whole, so that goods tightly wrapped together, can effectively prevent the transport process of goods in mutual dislocation and movement, at the same time, the adjustable tensile force can make hard products close, so that soft products tight, especially in the tobacco industry and the textile industry in the packaging.

4. Cost saving: the use of winding film packaging, can effectively reduce the cost of use. That is, the use of winding film is only about 15% of the original box packaging, heat contraction film about 35%, and carton packaging about 50%. Lidding film manufacturers say it will also reduce labor intensity, increase packaging efficiency and improve packaging quality.